Maintenance Planning in

Effective Maintenance Planning in for Optimal Fleet & Equipment Performance

Proper maintenance planning in is essential for keeping fleets and equipment running smoothly, reducing unexpected breakdowns, and minimizing repair costs. A proactive approach ensures operational efficiency, improves safety, and extends the lifespan of vehicles and machinery.

Key benefits of maintenance planning include:

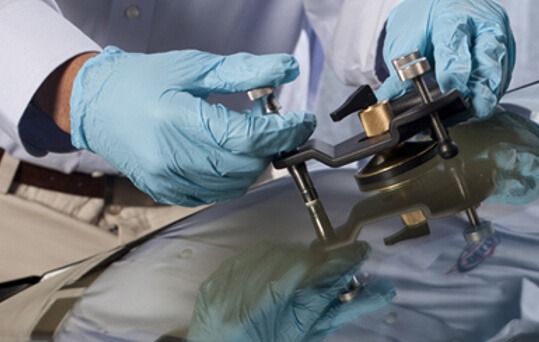

- Preventative Maintenance Scheduling: Reduce costly repairs by implementing regular inspections and servicing schedules.

- Minimized Downtime: Keep vehicles and equipment in peak condition to prevent disruptions in operations and ensure maximum productivity.

- Cost Control & Budgeting: Plan maintenance expenses effectively, reducing unplanned repair costs and improving financial forecasting.

- Compliance & Safety Assurance: Ensure all vehicles and machinery meet regulatory safety standards, reducing the risk of accidents and legal issues.

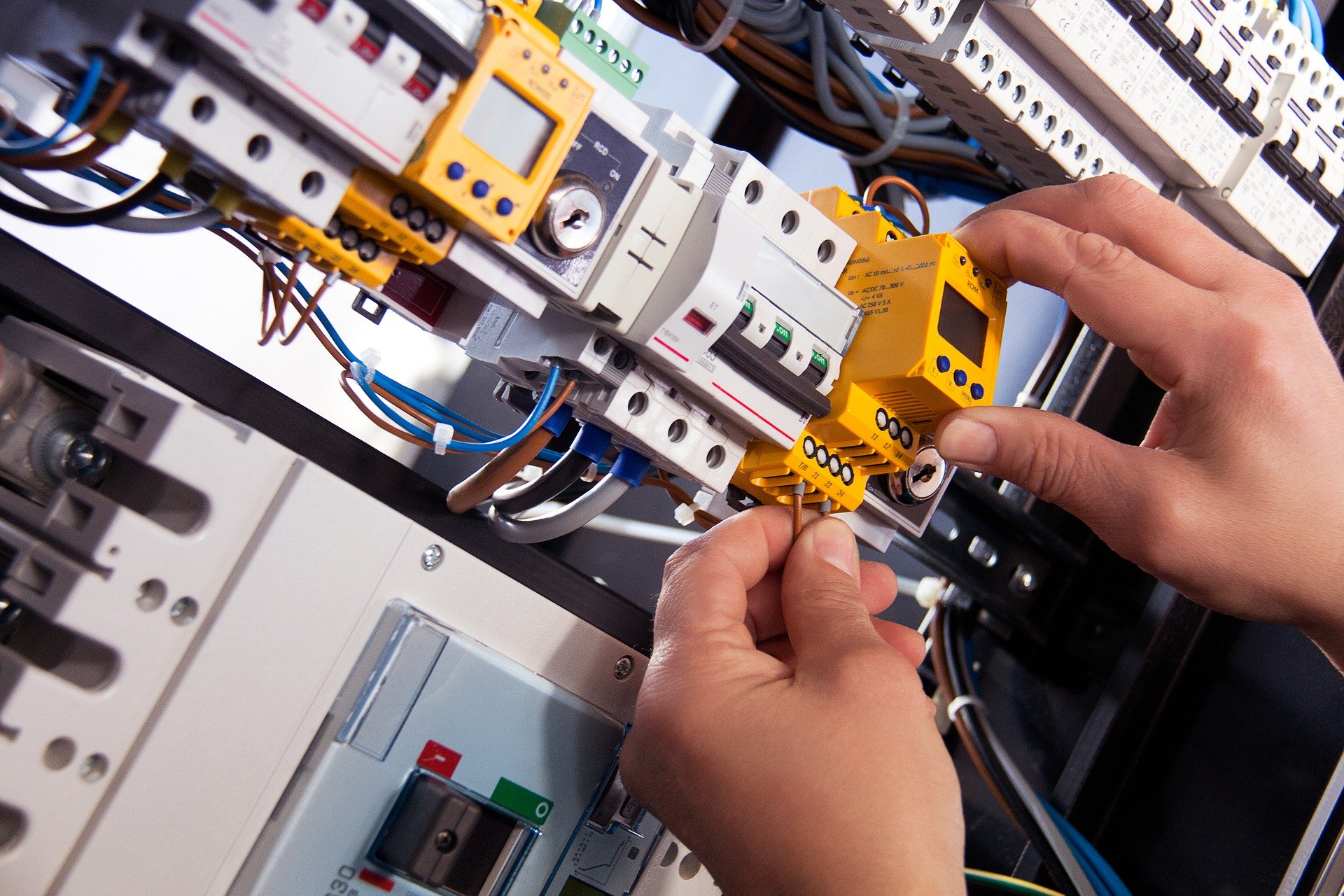

- Integration with Fleet Management Systems: Use advanced tracking and diagnostic tools to automate maintenance alerts and streamline service schedules.

By implementing a structured maintenance strategy, businesses can optimize asset utilization, extend equipment lifespan, and improve overall operational efficiency.

Streamline Your Maintenance Planning Today! Discover top-rated maintenance planning solutions in to keep your fleet and equipment in peak condition. From automated scheduling to real-time diagnostics, ensure seamless operations and cost-effective maintenance.

Need expert recommendations? Explore our maintenance manageme

Post ad

Post ad